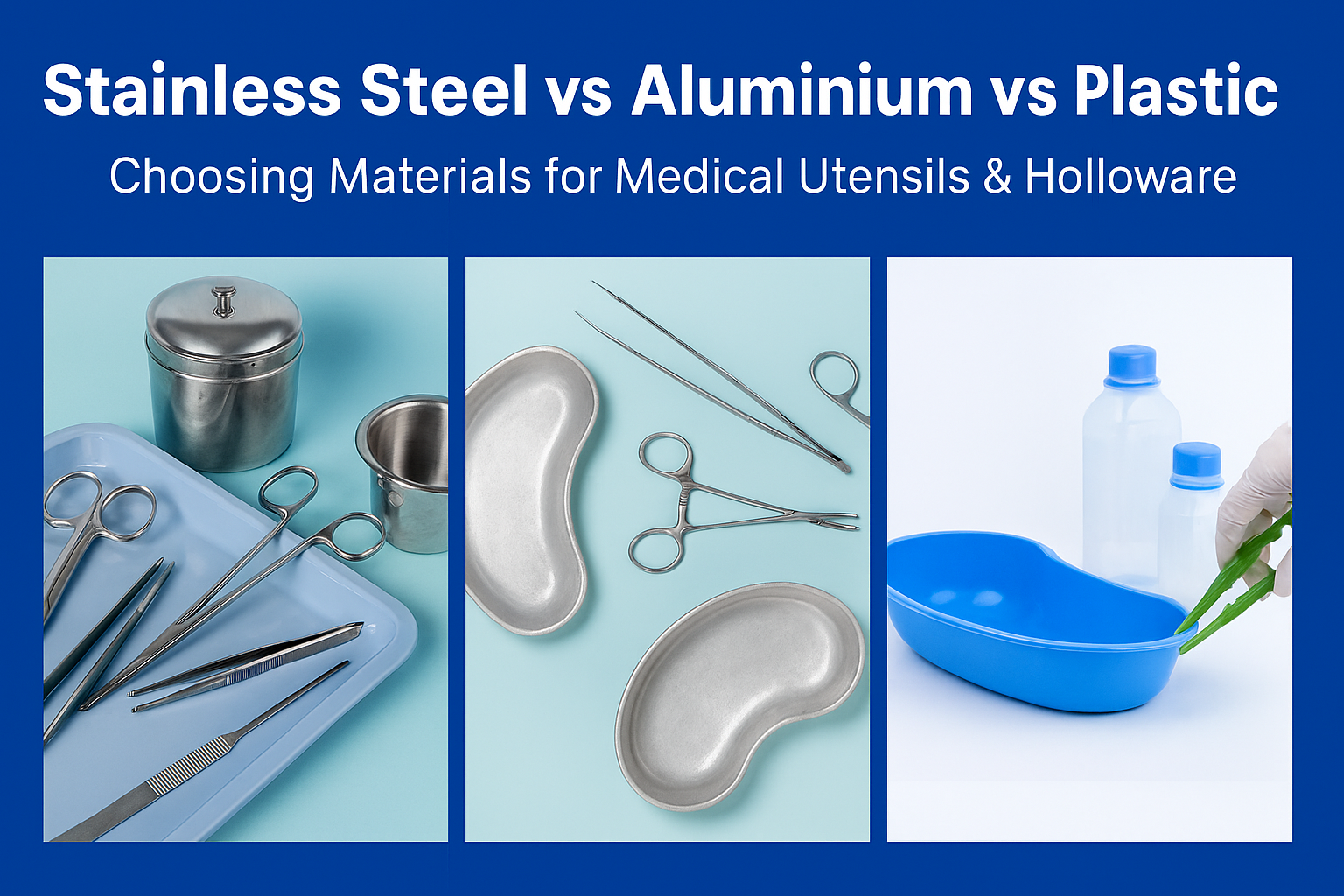

Many medical utensils and holloware are part and parcel of every hospital facility. It is important to choose the right medical utensils to ensure patient safety, infection control and cost efficiency.

The hospitals rely on materials that can withstand frequent sterilization, maintain structural integrity and meet strict hygiene standards. The most commonly used materials are stainless steel, aluminium and plastic.

Material Choice Important

Choosing between the stainless steel v/s aluminum, v/s plastic medical utensils is important in a healthcare facility because the material used in the medical tools and holloware affects several factors, including-

- Infection Control

- Chemical and Heat Resistance

- Durability during repeated Sterilization

- Cost over long-term usage

- Ease of handling for medical staff

Understanding how each material performs in these areas ensures good hygiene norms and reduces the contamination risk.

Let us understand the Pros and Cons of each material-

Stainless Steel

- Robust Strength: Stainless Steel is widely recognized as the most preferred material for medical utensils. The steel has the capacity to maintain structural strength in high-pressure sterilization environments like autoclaves. It does not crack, deform or deteriorate easily.

- Hygiene: One of the significant benefits of stainless steel medical utensils is that they are non-porous and have a corrosion-resistant surface. This prevents bacterial buildup. The steel can withstand autoclaving, steam and UV sterilization. This makes it ideal for long-term use in hospitals where instruments are cleaned many times a day.

- Corrosion and Rust Resistance: The high-grade stainless steel offers excellent corrosion resistance, ensuring that trays, bowls and containers do not chip or rust over time- even with heavy exposure to water, saline solutions and disinfectants.

- Cost-Efficiency: Stainless Steel has a higher upfront cost, but it is durable. The long life span of the stainless steel medical utensils reduces replacement expenses. Thus, most stainless steel medical and holloware items last for years with minimum maintenance.

What are the limitations of Stainless Steel Holloware?

- Higher Initial Investment

- Heavier than Aluminum or Plastic

- It can be noisy when handled or stacked.

Aluminum

- Lightweight: Aluminium Medical Utensils are lighter than stainless steel, making them convenient for use, especially in non-critical environments. The hospital staff finds it easier to carry the aluminum medical utensils and holloware easily during patient rounds.4

- Faster Heating and Cooling: Aluminium conducts heat quickly. This means the surface becomes hot and cold faster, which may not be ideal in hospital settings.

- Economical: Aluminum Holloware costs are less than stainless steel. They are ideal for emergency setups, budget-restricted healthcare setups and temporary wards.

What are the limitations of Aluminum Holloware?

- Dents and Deformation

- Lower Resistance to strong disinfectants

- Cannot withstand repeated autoclaving

- Can react with certain chemicals

- The surface may oxidize over time.

Plastic

- Cost-Effective: Plastic medical utensils are widely used in many healthcare setups due to their low cost and easy availability. They are used in situations where single-use devices are preferred to reduce cross-contamination risks.

- Designed for Single Use: They are designed for single use, including outpatient departments, diagnostic labs, isolation wards and short procedures where disposables improve hygiene.

What are the limitations of Plastic Holloware?

- Not ideal for autoclaving unless specially designed

- Can melt or warp under high heat

- Prone to scratches, encouraging bacterial growth

- Not a sustainable option

- Less Durable.

Stainless Steel v/s Aluminum v/s Plastic Holloware – Bird’s Eye Comparative Analysis

| Factor | Stainless Steel | Aluminum | Plastic |

| Durability | Excellent | Moderate | Low |

| Heat Resistance | High | Moderate | Low-Moderate |

| Sterilization Compatibility | Excellent | Limited | Limited |

| Hygiene | Excellent | Moderate | Moderate-Low |

| Initial Cost | High | Medium | Low |

| Long-Term Cost | Low | Medium | High |

| Environmental Impact | Low | Moderate | High |

| Use Cases | Critical Care, OT, ICU | General Wards, Transport | OPD, disposables |

Understanding Compliance Standards for Medical Grade Materials

Selecting material for medical utensils and holloware is beyond durability. It is all about meeting strict regulatory norms. Healthcare products must adhere to guidelines like ISO and CE certifications and hospital infection control protocols. Materials like stainless steel and medical-grade plastics undergo stringent testing for sterility, corrosion resistance, safety and biocompatibility.

It is important to choose material that meets these standards, help maintain hygiene and reduces contamination risks, thus improving patient safety.

High-Sterilization Environment- Which Material Survives in the Long-Run?

Frequent sterilization is a non-negotiable requirement in any healthcare setting. Materials react differently to autoclaving, steam, chemicals and UV sterilization. Stainless Steel consistently performs best, maintaining its structure and resisting corrosion even after many sterilizing cycles.

Aluminum may deform or oxidize over time, while plastic often cannot withstand high temperatures unless specially made for sterile applications. It is important that the hospitals and clinics understand how each material behaves under constant sterilization, helping choose options that are safe and reliable for long-term use.

Cost Comparison of Materials for Medical Instruments

Hospitals must consider long-term value apart from the initial purchase price. Stainless Steel, even though expensive upfront, lasts for years and requires minimal replacement. Aluminum offers moderate pricing but may need frequent replacements due to dents or corrosion.

Plastic is the cheap option initially, but it becomes costly over time because of single-use disposal and high replacement rates. A clear cost analysis helps facilitate choosing the material that balances budget and performance.

Final Verdict- Stainless Steel Rules the Roost

While aluminum and plastic have their own advantages, stainless steel clearly stands out for its –

- Exceptional Durability

- Superior Hygiene

- Long-Term Cost Efficiency

- Compatibility with all sterilization techniques

When it comes to patient safety and infection control, stainless steel is the most reliable and recommended material for medical utensils and holloware.

FAQs

- Which is the best material for medical utensils?

Stainless Steel is the best material for medical utensils and holloware. United Poly manufactures the best quality medical materials aligned with your healthcare facility’s needs. - What are the uses of plastic medical utensils?

Plastic medical utensils are used for single-use or short medical procedures to maintain hygiene and prevent cross-contamination. - What makes United Poly stand out as the reliable manufacturer and exporter of medical utensils and holloware?

United Poly stands out for its best quality materials, strict quality control, durable designs and trusted global export norms in medical utensils and holloware.